About Northville Woodturning

Our Products

Our Commitment to Quality

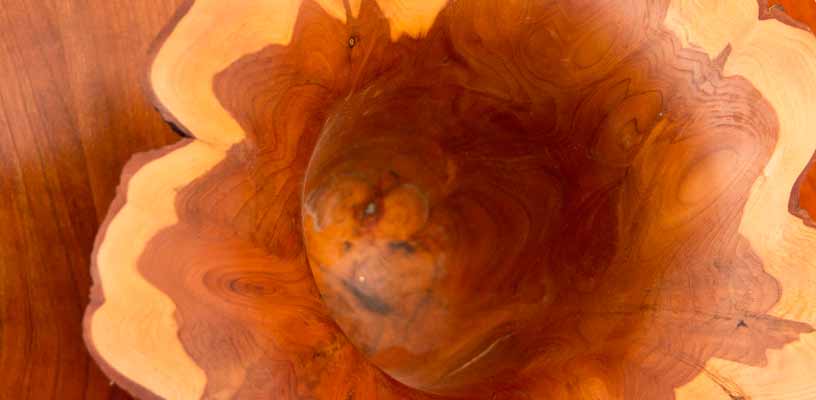

Northville Woodturning is not focused on quanity of items but instead on the quality of each item. From the woods I select, design of each piece, and finishes I use, the focus is always on quality. I want the owner of my product to feel as good about it as I do.

The Process

- Sketch my idea onto paper

- Select the perfect piece of wood

- Cut a blank on the bandsaw

- Mount blank onto the lathe

- Shape into design that was sketched

- Sand from 150-1200 grit paper

- Apply multiple coats of finish

- Buff wax and finish to a shine